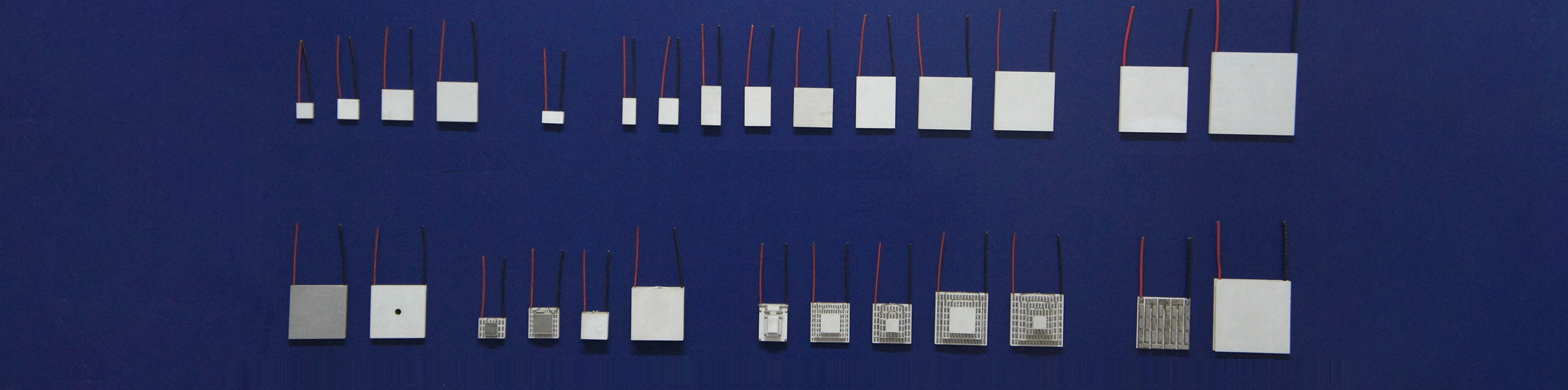

Iimodyuli zokupholisa ze-thermoelectric, imodyuli ye-thermoelectric, imodyuli ye-TEC, isixhobo se-peltier Indlela yokufaka

Ngokubanzi kukho iindlela ezintathu zokufakaimodyuli ye-thermoelectricukuwelda, ukubopha, ukucinezela kunye nokulungisa ibholiti. Kwimveliso yeyiphi indlela yokufakela, ngokweemfuno zemveliso, ukumisela, ngokubanzi, ukufakela ezi ntlobo zintathu, okokuqala ukusebenzisa umqhaphu wotywala ongenamanzi kuya kubai-thermoelectric coolerIindawo zamacala omabini zicocekile, ipleyiti ebandayo kunye nomphezulu wokufakelwa kwepleyiti yokupholisa kufuneka zicutshungulwe, ubucaba bomphezulu abudluli kwi-0.03mm, kwaye bucocekile, ezi zilandelayo ziintlobo ezintathu zokufakelwa kwenkqubo yokusebenza.

1. Ukuwelda.

Indlela yokufaka i-welding ifuna ukuba umphezulu wangaphandle we-Imodyuli yeTECkufuneka zenziwe ngesinyithi, kwaye ipleyiti ebandayo kunye nepleyiti yokupholisa nazo kufuneka zikwazi ukunyibilikisa (ezifana: ipleyiti ebandayo yobhedu okanye ipleyiti yokupholisa). Xa ufaka ipleyiti ebandayo, ipleyiti yokupholisa kunye nesixhobo se-peltier, i-peltier element, iimodyuli zokupholisa ze-thermoelectric, imodyuli ye-TEC, ipleyiti ebandayo kunye nepleyiti yokupholisa ye-thermoelectric ziyafudunyezwa kuqala, (ubushushu kunye nendawo yokunyibilikisa ye-solder ziyafana), i-solder enobushushu obuphantsi phakathi kwama-70 ° C kunye nama-110 ° C iyanyibilika kumphezulu wofakelo. Emva koko umphezulu oshushu wesixhobo se-peltier, imodyuli ye-peltier, imodyuli ye-thermoelectric, isixhobo se-TEC kunye nomphezulu wokufakela wepleyiti yokupholisa, umphezulu obandayo wemodyuli ye-thermoelectric, isixhobo se-thermoelectric kunye nomphezulu wokufakela wepleyiti ebandayo zihambelana ngokufanayo kwaye zijikeleza i-extrusion ukuqinisekisa ukuba umphezulu osebenzayo uhambelana kakuhle emva kokupholisa. Indlela yokufaka iyinkimbinkimbi ngakumbi, ayilula ukuyigcina, kwaye isetyenziswa rhoqo kwiziganeko ezikhethekileyo.

2. Iglu.

Ufakelo lweglueI-thod kukusebenzisa iglu ene-thermal conductivity elungileyo, egqunywe ngokulinganayo kumphezulu wokufakelwa kwemodyuli yokupholisa yeThermoelectric,, ipleyiti ebandayo kunye nepleyiti yokupholisa. Ubukhulu beglue yi-0.03mm, umphezulu obandayo noshushu wesixhobo se-peltier, iseli ye-peltier, imodyuli ye-TEC, imodyuli ye-thermoelectric kunye nomphezulu wokufakelwa kwepleyiti ebandayo kunye nepleyiti yokusasaza ubushushu zikhutshiwe ngokudibeneyo, kwaye zijikeleziswa ngobunono ngasemva nangaphambili ukuqinisekisa unxibelelwano olufanelekileyo lomphezulu woqhagamshelwano, kwaye umoya ubekwa iiyure ezingama-24 ukuze uphile ngokwendalo. Indlela yokufaka isetyenziswa ngokubanzi ukulungisa ngokusisigxina isixhobo sokupholisa se-thermoelectric, iseli ye-peltier, isixhobo sokupholisa se-thermoelectric, kwindawo yepleyiti yokusasaza ubushushu okanye ipleyiti ebandayo.

3. Ukucinezelwa kunye nokulungiswa kwe-stud.

Indlela yokufaka ucinezelo lokulungisa i-stud kukugquma ngokulinganayo umphezulu wofakeloimodyuli yepeltieripleyiti ebandayo kunye nepleyiti yokusasaza ubushushu enomaleko omncinci wegrisi ye-silicone eshushu, ubukhulu bayo bumalunga ne-0.03mm. Emva koko umphezulu oshushu wei-peltier coolerkunye nomphezulu wokufakelwa kwepleyiti yokupholisa, umphezulu obandayo wezixhobo ze-peltier, iimodyuli zokupholisa ze-thermoelectric kunye nomphezulu wokufakelwa kwepleyiti ebandayo zihambelana ngaxeshanye, kwaye ujikeleze kancinci imodyuli ye-TEC, ubuyele umva nangaphambili kwemodyuli ye-thermoelectric, ukhuphe igrisi yobushushu obuninzi, qiniseka ukuba umphezulu wokusebenza uhambelana kakuhle, uze uqinise phakathi kwepleyiti yokupholisa, imodyuli ye-Thermoelectric, imodyuli ye-Peltier, imodyuli ye-TEC, imodyuli yokupholisa ye-thermoelectric kunye nepleyiti ebandayo ngezikrufu, amandla okubopha kufuneka afane, angagqithisi okanye alula kakhulu. Ifriji enzima kulula ukuyityumza, kwaye ukukhanya kulula ukubangela ubuso bokusebenza bungaqhagamshelani. Ukufakelwa kulula, kuyakhawuleza, kulula ukuyilungisa, kuthembekile kakhulu, okwangoku yeyona isetyenziswa kakhulu kwimveliso yendlela yokufakela.

Ezi ndlela zintathu zokufakela ukuze kufezekiswe isiphumo esihle sokupholisa, ukusetyenziswa kwezinto zokukhusela phakathi kwepleyiti ebandayo kunye nepleyiti yokupholisa, ukusetyenziswa kwesixhobo sokucoca ubushushu, ukuze kuncitshiswe utshintsho olushushu nolubandayo, ubungakanani bepleyiti ebandayo yokupholisa ye-thermoelectric kunye nepleyiti yokupholisa buxhomekeke kwindlela yokupholisa kunye nobukhulu bamandla okupholisa, ngokwemeko yesicelo.

Imodyuli yokupholisa ye-thermoelectric TES1-01009LT125 Inkcazelo

Ubungakanani: 0.9A,

Ubukhulu: 1.3V

Ubuninzi beQ: 0.65W

Ubuninzi beDelta T: 72C

I-ACR: 1.19﹢/﹣0.1Ω

Ubungakanani: 2.4×1.9×0.98mm

Imodyuli ye-thermoelectric ejikelezayo nesembindini ye-TES1-13905T125 Inkcazelo

Ubushushu obushushu ecaleni bungama-25 C,

Ubungakanani: 5A,

Umax:15-16 V

I-Qmax:48W

Ubuninzi beDelta T: 67 C

Ubude: 3.2+/- 0.1mm

Ubukhulu: Ububanzi bangaphandle: 39+/- 0.3mm, Ububanzi bangaphakathi: 9.5mm +/- 0.2mm,

Ubude bentambo yentambo yePVC ye-22AWG: 110mm +/- 2mm

Imodyuli ye-thermoelectric TES1-3202T200 Iinkcukacha

Ubungakanani: 1.7-1.9A,

Ubuninzi: 2.7V

Ubuninzi beQ: 3.1W

Ubuninzi beDelta T: 72C

I-ACR: 1.42-1.57Ω

Ubungakanani: 6 × 8.2 × 1.6-1.7mm

Ixesha leposi: Novemba-28-2024